In steelmaking and rolling production, equipment operates under long-term high temperature, heavy load, and continuous operation.Lubrication failure can directly lead to downtime, production accidents, or even equipment scrapping. Therefore, the DUAL-LINE/TWO-LINE automatic centralized lubrication system has become an important means to ensure the stable operation of equipment in steel plants.

In the past, a common centralized lubrication configuration in steel plants was the ZPU08/14 lubrication pump combined with DSG / DSL dual-line metering devices.

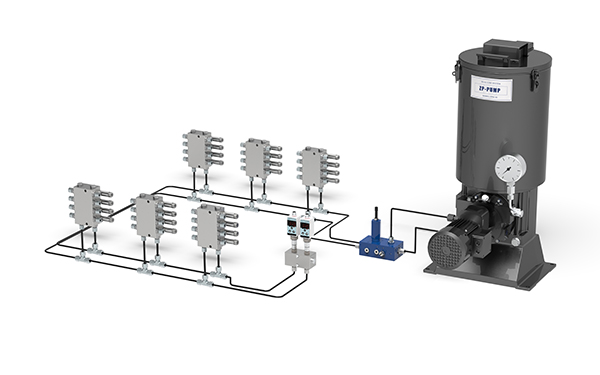

This system is mature in structure and suitable for covering large-scale equipment lubrication requirements.With continuous technological advancement, CISOLUBE has now introduced ZP lubrication pumps with DSG / DSL dual-line metering devices,bringing customers in the steel industry a more efficient and reliable centralized lubrication solution.

The ZP series lubrication pumps are specially designed for large-scale equipment such as steel plants, cement plants, metallurgy, mining, and port machinery.They provide stable and reliable lubrication supply in harsh industrial environments.They are suitable for high-viscosity grease and can deliver grease uniformly over long pipeline distances.

- Rugged and durable

- Easy maintenance

- Three displacement options available

- Compatible with ultrasonic level control device

- Built-in filter

- Models: ZP08 / ZP14 / ZP24

- Displacement: 8000 ml/h, 14000 ml/h, 24000 ml/h

- Drive speed: 60 rpm (ZP08), 90 rpm (ZP14 / ZP24)

- Working pressure: up to 40 MPa

- Reservoir capacity: 40L / 60L / 100L

- Applicable lubricants: NLGI grade 0#–2# grease

- Safety valve: fixed setting at 410 bar

- Noise level: <70 dB(A)

- Operating temperature: -40℃ to +80℃

- Motor power: 0.75 KW

- Voltage: 380–415 V

In steel plant equipment, the number of lubrication points is large and widely distributed, especially in rolling mills and continuous casting machines,where lubrication precision requirements are extremely high.The CISOLUBE DSG dual-line metering devices ensure even grease distribution to each lubrication point in the system, guaranteeing that every component receives sufficient lubrication.

- Easy installation

- Solid block structure for enhanced durability

- Effective operation across a wide temperature range

- Easy monitoring

- Outlets: 2–8

- Working pressure: up to 40 MPa / 5800 psi

- Displacement: 0–2.2 ml/cycle (adjustable); fixed displacements: 0.55, 1.1, 1.65, 2.2 ml/cycle

- Applicable lubricants: NLGI grade 0#–3# grease

- Operating temperature:

* NBR seals: -40℃ to +100℃

* FKM seals: -20℃ to +180℃

- Connection size: inlet G3/8, outlet G1/4

- Material: galvanized steel

Unlike the DSG metering devices, the DSL dual-line metering devices offer greater flexibility in displacement adjustment and adaptability.They can meet diverse lubrication demands, especially in equipment with highly varied lubrication requirements.

- Multiple outlet options configurable per equipment requirements

- Wider displacement adjustment range suitable for various lubrication environments

- Compact structure, easy installation and maintenance

- Made from high-quality carbon steel with white zinc plating for strong corrosion resistance

- Outlets: 2–8

- Operating temperature:

* NBR: -40℃ to +100℃

* FKM: -20℃ to +180℃

- Working pressure: up to 40 MPa / 5800 psi

- Displacement: 0–5 ml/cycle (adjustable); fixed displacements: 1.25, 2.5, 3, 3.75, 5 ml/cycle

- Applicable lubricants: NLGI grade 0#–3# grease

- Inlet thread: G3/8

- Outlet thread: G1/4

- Material: carbon steel with white zinc plating

CISOLUBE is committed to providing global customers with efficient and reliable centralized lubrication system, covering single-line, dual line lubrication systems, and progressive lubrication methods.These systems are widely applied in industries such as steel, cement, mining, building materials, construction machinery, and port equipment.

By combining the ZP lubrication pumps with DSG and DSL dual-line metering devices,CISOLUBE delivers stable and reliable automatic lubrication solutions to steel plant customers,helping reduce equipment failure rates, extend service life, and improve production efficiency.Whether for new steel plant projects or upgrading lubrication systems for older equipment,CISOLUBE provides complete technical support and product services,helping steel enterprises achieve efficient operations and sustainable development.