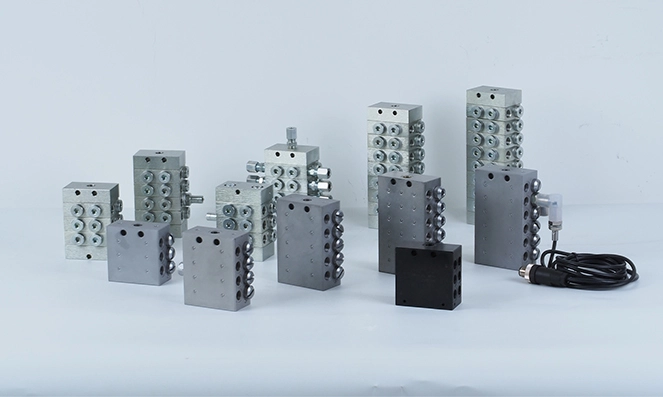

This automatic progressive lubrication system sequentially dispenses lubricant to various points. It's ideal for machines with many lubrication points and ensures precise lubrication distribution.

This centralized progressive lubrication systems, designed with advanced technology, sequentially dispenses lubricant to various points in a machine. Central progressive lubrication system is an ideal solution for machines that have numerous lubrication points, such as industrial machinery or heavy-duty vehicles. The automatic progressive lubrication systems ensure precise lubrication distribution, which is crucial for the smooth operation and longevity of the machine. Central progressive lubrication systems reduce the risk of over or under lubrication, which can lead to mechanical failures or unnecessary wear and tear. Furthermore, centralized progressive lubrication systems also save time and resources by automating the lubrication process, eliminating the need for manual lubrication. This series progressive lubrication system is not only efficient but also contributes to the overall maintenance and performance of the machine. Cisolube centralized grease lubrication system is a reliable and cost-effective solution for maintaining optimal lubrication in complex machinery.

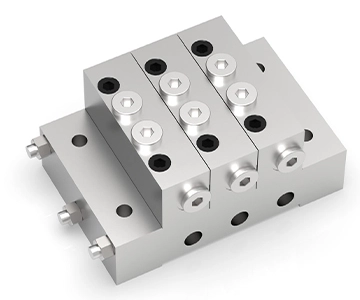

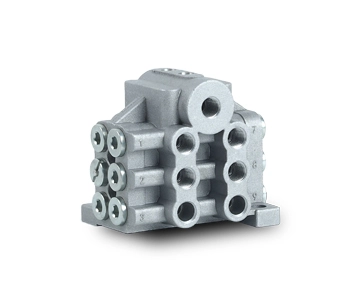

Compact, flexible kit

Monitored function

Channels flow through completely

CISO Progressive Lubrication Systems have wide range of use

CISO Progressive Lubrication Systems have integrated return valve inside

A —GT lubrication pump

B —GM lubrication pump

C—GP203 lubrication pump

D—GP205 lubrication pump

E—GT-X lubrication pump

F—GT-HEAVY lubrication pump

G—GP212 lubrication pump

1 —Outlet relief valve elements

2 —Main line

3 —Filter

4 —pressure switch

5 —progressive distributor(1generation)

6 —progressive distributor(2generation)

7 —progressive distributor(2generation)

8 —progressive distributor(3generation)

9 —Function control

10 —Fault Monitoring

11 —Pipes and hoses

12 —Line to the lubrication point

13 —Controller

The series progressive lubrication systems works by pumping lubricant into the main line, which then gets distributed to various points through the progressive distributors. The amount of lubricant each point receives is controlled and precise.

The series progressive lubrication systems comprise a feed pump, progressive distributors, necessary pipelines, threaded pipe fittings, fastening components, and pressure indicators.

The series progressive lubrication systems should be assembled on an easily accessible position of the machine, and the progressive distributor should be assembled as close to the lubrication points as possible.

The design depends on the number of lubrication points to be connected and the grease dose requirements. The pipeline must withstand maximum pump pressure.

The type of lubricant used depends on the specific requirements of the machinery being lubricated. It's best to consult with a lubrication specialist for specific recommendations.

| Feature | Progressive Lubrication Systems | Single-Line Lubrication Systems | Dual-line Lubrication Systems | Chain Lubrication Systems |

| Definition | Progressive lubrication system is an efficient lubrication system used for mechanical equipment, providing lubricant progressively to different parts of the equipment to ensure each part receives an adequate amount of lubrication. |

The lubrication pump automatically delivers lubricant to the lubricant dispenser via a single supply line. Each dispenser serves only one lubrication point and can be adjusted to provide the exact dose of grease or oil required. |

Dual-line systems can be used on large systems with dispersed lubrication points that require varying lubrication quantities These systems utilize two main lines that are supplied alternately with lubricant from a high-pressure pump. |

Chain lubrication system is a system used to protect and maintain chains of mechanical equipment. It works mainly by providing the right amount of lubricant to reduce chain friction and wear, and to maintain chain flexibility and operating efficiency. A chain lubrication system usually includes a tank, lines, and brushes. These components work together to ensure that the chain surface is always properly lubricated, prolonging the life of the chain and drive system, reducing maintenance costs, and improving equipment reliability and efficiency. |

| Basic Components | A —GT auto lube pump B —GM auto lubrication pump C—GP203 lubrication pump D—GP205 lubrication pump E—GT-X lubrication pump F—GT-HEAVY lubrication pump G—GP212 lubrication pump Outlet relief valve elements Main line Filter Pressure switch Progressive distributor(1generation) Progressive distributor(2generation) Progressive distributor(2generation) Progressive distributor(3generation) Function control Fault Monitoring Pipes and hoses Line to the lubrication point Controller |

A — C-flow lubrication pump D — GTS single line lubrication pump E — GMS electric lubrication pump F — GT-MAX lube grease pump Return solenoid valve assembly Pressure gauge Pipelines Filter Tee branching pleces Pipe clamps Four branching pleces Volumetric distributor Check device(pressure switch) Line to the lubrication point Controller |

DSG Dual-line Metering Devices DSL Dual-line Metering Devices DSKH Metering Devices WP-C Electric Change-Over Valve DU-C Hydraulic Change-Over Valves MC-ⅠSystem Control Box EPW End-of-line Pressure Switches |

Oil Tank Brushes High-Pressure Flexible Pipe |

| Working Principle | The lubricant is pumped through the main lines to the progressive distributor with the pump. The lubricant is elivered "progressively" to the friction point. The circulation of a progressive distributor is monitored optically or electrically. |

The dosing values are impinged on the main line with the pump – dynamically operating metering valves with a pressure surge, static operating dosing elements with slow pressure build-up. These thus transfer the respective quantity of the lubricant to the friction point.During the following relief phase, the lubricant is restacked in the dosing valves for the next lubrication process. |

CISO dual-line systems can be used on large systems with dispersed lubrication points that require varying lubrication quantities. These systems utilize two main lines that are supplied alternately with lubricant from a high-pressure pump via a change-over valve at up to 400 bar (5 800 psi) Branch lines, along the main lines, are connected with dual-line metering devices to supply a large volume of lubricant to the lubrication points Within large dual-line systems, end-of-line pressure switches are used to control and monitor the system. |

The chain lubrication system transfers the lubricant from the storage tank to the brushes through the lubrication pump, and through the brushes the lubricant is applied to the chain to form a lubricating film, which reduces the chain friction and wear. |

| Advantages | Compact, flexible kit Monitored function Channels flow through completely Wide range of use |

Connecting numerous lubrication points Smallest dosing quantities Compact construction For oil or fluid grease Low cost and high efficiency Easy assembly |

Reliable Simple to service Ultrasonic low- and high-level control options Built-in lubricant filter |

Compact structure and easy expansion No need for a distributor The pipes are smooth and have no residue Adjustable displacement |

CISO-Your Partner in Advanced Central Lube System