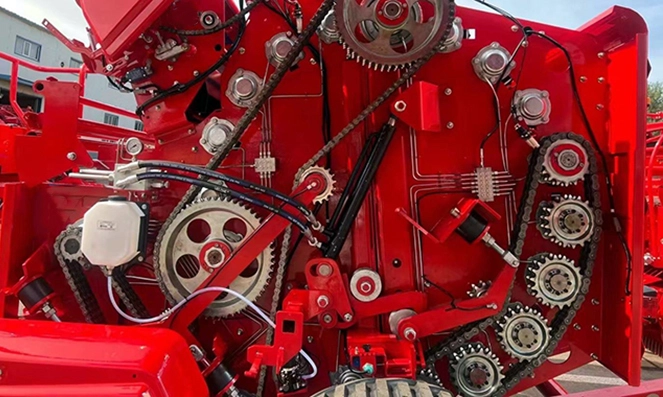

Automatic Chain lubrication system is a system used to protect and maintain chains of mechanical equipment. Industrial chain lubrication systems work mainly by providing the right amount of lubricant to reduce chain friction and wear, and to maintain chain flexibility and operating efficiency. Central chain lubrication systems usually include a tank, lines, and brushes. These components work together to ensure that the chain surface is always properly lubricated, prolonging the life of the chain and drive system, reducing maintenance costs, and improving equipment reliability and efficiency.

Compact structure and easy expansion

No need for a distributor

Pipes are clear and free of residue

High performance cost ratio

Stable flow rate

Automatic chain lubrication systems reduce chain friction and wear by automatically supplying the right amount of lubricant, maintaining chain flexibility and operational efficiency. Key features include convenient automation, reduced maintenance frequency and costs, extended chain life, improved equipment reliability, ensured operational efficiency and safety, and applicability to various industrial equipment chains with Cisolube centralized grease lubrication system.

Chain lubrication systems are essential for equipment utilizing chain drives, including harvesters, balers, and mowers. Effective lubrication plays a crucial role in minimizing impact, reducing friction, and prolonging the chain's lifespan.The more commonly used ones are PMV chain lubrication pumps and PMN chain lubrication pumps.

The PMV Chain Lubrication pump offers several noteworthy features. Its compact structure and easy expandability make it versatile for various applications. Unlike traditional systems, it eliminates the need for a distributor, simplifying installation and maintenance. The smooth pipes prevent residue buildup, ensuring uninterrupted lubrication. Additionally, its multiline output capability enables efficient lubrication across multiple points, enhancing equipment performance. With adjustable displacement, users can fine-tune the lubrication volume as per requirements, further optimizing chain maintenance.

On the other hand, the PMN Chain Lubrication pump boasts a robust plunger structure and a solid pump body, eliminating the need for a motor and controller. This design simplifies the system's operation and reduces maintenance complexity. Equipped with inlet and outlet check valves, it ensures precise lubricant delivery and prevents backflow, enhancing system reliability. The lubricating pumps's high-performance cost ratio makes it a cost-effective choice for various industrial applications. Similar to the PMV pump, it also offers adjustable displacement, allowing users to customize lubrication levels based on specific operational needs.

Both PMV and PMN Chain Lubrication pumps provide efficient and reliable lubrication solutions for chain-driven equipment. Their features cater to different requirements, offering flexibility and cost-effectiveness in maintenance. Whether in agricultural machinery or industrial equipment, these pumps contribute significantly to extending chain life, reducing downtime, and optimizing equipment performance.

| Feature | Progressive Lubrication Systems | Single-Line Lubrication Systems | Dual-line Lubrication Systems | Chain Lubrication Systems |

| Definition | Progressive lubrication system is an efficient lubrication system used for mechanical equipment, providing lubricant progressively to different parts of the equipment to ensure each part receives an adequate amount of lubrication. |

The lubrication pump automatically delivers lubricant to the lubricant dispenser via a single supply line. Each dispenser serves only one lubrication point and can be adjusted to provide the exact dose of grease or oil required. |

Dual-line systems can be used on large systems with dispersed lubrication points that require varying lubrication quantities These systems utilize two main lines that are supplied alternately with lubricant from a high-pressure pump. |

Chain lubrication system is a system used to protect and maintain chains of mechanical equipment. It works mainly by providing the right amount of lubricant to reduce chain friction and wear, and to maintain chain flexibility and operating efficiency. A chain lubrication system usually includes a tank, lines, and brushes. These components work together to ensure that the chain surface is always properly lubricated, prolonging the life of the chain and drive system, reducing maintenance costs, and improving equipment reliability and efficiency. |

| Basic Components | A —GT auto lube pump B —GM auto lubrication pump Outlet relief valve elements Main line Filter Pressure switch Progressive distributor(1generation) Progressive distributor(2generation) Progressive distributor(2generation) Progressive distributor(3generation) Function control Fault Monitoring Pipes and hoses Line to the lubrication point Controller |

A — GT-MAX lube grease pump B — GMS electric lubrication pump C — C-flow lubrication pump Return solenoid valve assembly Pressure gauge Pipelines Filter Tee branching pleces Pipe clamps Four branching pleces Volumetric distributor Check device(pressure switch) Line to the lubrication point Controller |

DSG Dual-line Metering Devices DSL Dual-line Metering Devices WP-C Electric Change-Over Valve DU-C Hydraulic Change-Over Valves MC-ⅠSystem Control Box EPW End-of-line Pressure Switches |

Oil Tank Brushes High-Pressure Flexible Pipe |

| Working Principle | The lubricant is pumped through the main lines to the progressive distributor with the pump. The lubricant is elivered "progressively" to the friction point. The circulation of a progressive distributor is monitored optically or electrically. |

The dosing values are impinged on the main line with the pump – dynamically operating metering valves with a pressure surge, static operating dosing elements with slow pressure build-up. These thus transfer the respective quantity of the lubricant to the friction point.During the following relief phase, the lubricant is restacked in the dosing valves for the next lubrication process. |

CISO dual-line systems can be used on large systems with dispersed lubrication points that require varying lubrication quantities. These systems utilize two main lines that are supplied alternately with lubricant from a high-pressure pump via a change-over valve at up to 400 bar (5 800 psi) Branch lines, along the main lines, are connected with dual-line metering devices to supply a large volume of lubricant to the lubrication points Within large dual-line systems, end-of-line pressure switches are used to control and monitor the system. |

The chain lubrication system transfers the lubricant from the storage tank to the brushes through the lubrication pump, and through the brushes the lubricant is applied to the chain to form a lubricating film, which reduces the chain friction and wear. |

| Advantages | Compact, flexible kit Monitored function Channels flow through completely Wide range of use |

Connecting numerous lubrication points Smallest dosing quantities Compact construction For oil or fluid grease Low cost and high efficiency Easy assembly |

Reliable Simple to service Ultrasonic low- and high-level control options Built-in lubricant filter |

Compact structure and easy expansion No need for a distributor The pipes are smooth and have no residue Adjustable displacement |

CISO-Your Partner in Advanced Central Lube System