Call Us

+8615864607907

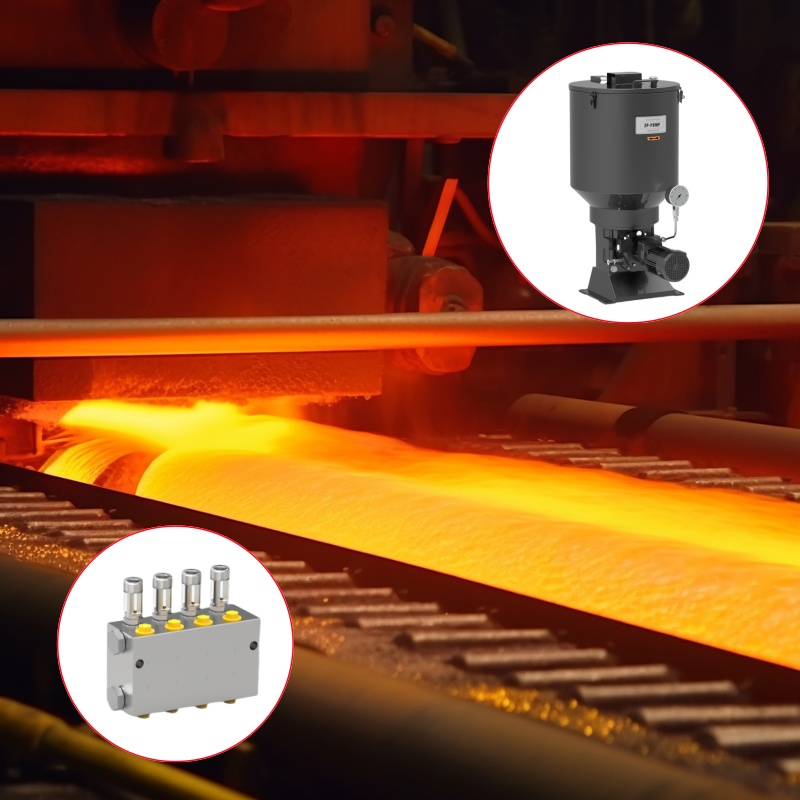

Agricultural machinery often operates in harsh environmental conditions, such as high temperatures, high humidity, and dusty environments. These conditions place high demands on the lubrication performance of bearings and chains. Ciso lubrication systems can provide customized professional lubrication solutions for all types of agricultural machinery.

Know More

CN

CN

EN

EN

ru

ru  fr

fr  de

de  es

es  pt

pt  ar

ar  hi

hi  id

id  tr

tr  it

it  pl

pl  nl

nl